Dokumentation

Komplett och uppdaterad service- och produktdokumentation tillgänglig för visning och nedladdning. Välj en kategori för att inleda din sökning.

InfoTeleves 70 (march)

- General Information: A pioneering vision in electronic manufacturing technologies since 1983

- Televes in the world: ISE 2024-SPECIAL, Congresso AHP and CES 2024

- Televes Corporation: Televes Corporation obtains the EN-9100 AENOR certification for aerospace microelectronics

- Our people: Germán Bentancur. Digital Marketing Technician

- FAQs: What does “suitable for the industrial environment” mean?

- Televes facilities: Volta do Castro'(Santiago de Compostela, Galicia - Spain)

- Ideas: How to use the MOSAIQ6 meter all day long without having to charge it?

- Training: Single-mode fibre classification according to ITU-T G.65x model

- Announcement: CIES Crosswalk. SMART LIGHTING TO PROTECT CITIZEN SAFETY

General Information

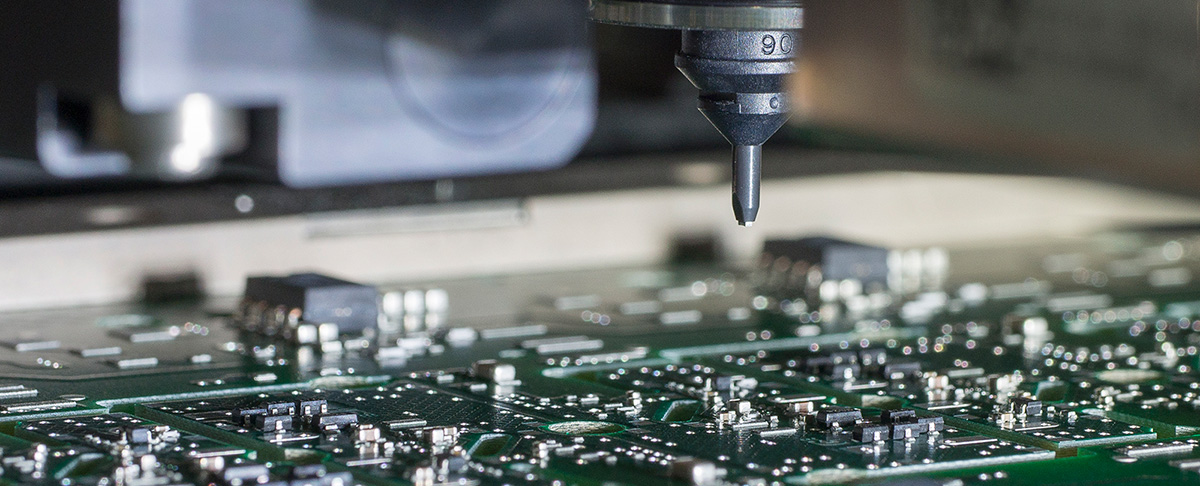

A pioneering vision in electronic manufacturing technologies since 1983

Televes set a clear strategic direction in state-of-the-art manufacturing from 1983 when we became the first company in our industry in Europe to embrace surface mount component technologies, acquiring the first SMD machine that Siemens exported outside Germany. This bold step catapulted Televes onto a path of automation and robotisation that has defined its brand identity, recognised and valued in the market to this day.

At a time when SMD technology was unknown in Spain and despite the high costs, Televes strategically envisioned a future of advanced manufacturing. Not only did we acquire the machines, but we also worked hand in hand with Siemens engineers, suggesting adaptations and improvements that the manufacturer incorporated into subsequent series, establishing a partnership that continues to this day.

In 2010, Televes reaffirmed its pioneering position by becoming the first customer worldwide to acquire the Siemens SiPlace CA4, the first generation of SMD machines capable of mixing die components from wafers with traditional components. This milestone placed Televes at the global technological forefront and ushered in the era of microelectronics.

Our commitment to die components, extracted directly from the wafer, demonstrates our commitment to innovation. At Televes, we have explored soldering on wafers without tin terminations, with surprising results. Today, with over 5 million dies on the market, Televes is at the technological forefront of microelectronics in Europe.

We design and integrate dies with MMIC technology, and we are progressing towards integrated circuits based on gallium nitride.This process has involved a significant redesign of our assembly lines, reflecting the commitment of our engineering and industrialisation teams.

This acquired know-how allows Televes and other Televes Corporation companies, such as Maxwell Applied Tech and GCE, to strategically position themselves in key sectors such as Defence, Aeronautics and Automotive. We actively participate in the Strategic Projects for Economic Recovery and Transformation (PERTE Chip), allocating a public investment of more than 30,000 million euros to boost the microelectronics and semiconductor industry, thus contributing to European technological sovereignty.

In Europe’s new industrial revolution, microelectronics is a strategic pillar, and Televes Corporation is proud to be an integral part of this process. Without forgetting our origins, we think back to 40 years ago, when we believed in the possibility of assembling SMD components, an essential precursor of our current capabilities in MMIC technologies since 2010

In 2010, Televes became the first Siemens customer worldwide to acquire a SiPlace CA4 machine. This is when we began working with wafers, ushering in the era of microelectronics.

Televes in the world

ISE 2024-SPECIAL, Congresso AHP and CES 2024

ISE 2024 SPECIAL (Barcelona) 30 jan - 2 feb

ISE 2024: An exciting success for Televes

ISE (Integrated Systems Europe) is the world’s leading trade fair for audiovisual technology and professional electronics. It is held annually in Barcelona and brings together the industry’s leading manufacturers, suppliers and distributors. In the 2024 edition, ISE was attended by more than 1,300 exhibitors and 80,000 visitors from 150 countries.

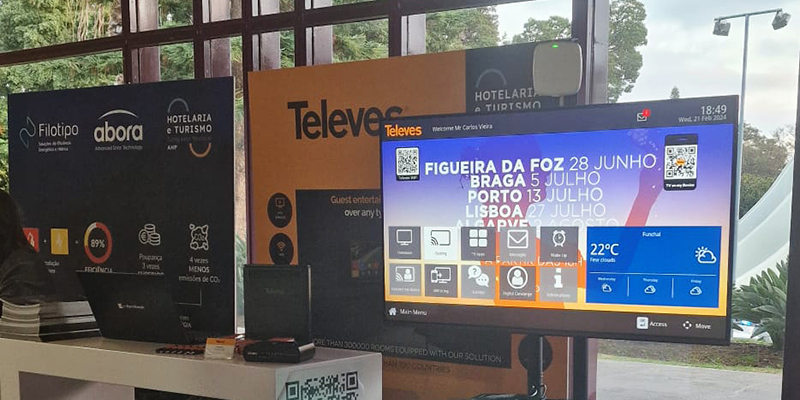

Televes participated in ISE 2024 for the first time with a large stand in Hall 5. There we presented our latest innovations in solutions for the digitisation processes of the hotel industry, with two main axes:

specially designed for Hospitality environments

Solutions for hotel digitisation

The Hospitality sector was the main focus of our presence at the event. In this edition of ISE we focused on our OLT 512 EVO for fibre optic network infrastructures, specially designed for Hospitality environments where the number of services to be deployed and lifted in the ONT is much higher than what an Operator OLT is capable of lifting.

It also allows profile-based configurations and does not require the ONU/ONT to be associated with a PON, facilitating maintenance works.

Guillermo Fernández, Technical Director of Hospitality at Televes,summed up his feelings of the event, commenting:

“We are very satisfied with the results of our participation in ISE 2024.

The profile of the visitors, focused on integrators and installers of audiovisual services in buildings, coincided exactly with our target audience. We had the opportunity to present them our solutions for the digitisation of buildings and efficient resource management, and the response was very positive”.

Our Hospitality Area Director in Spain, José Luis Pineda,was also present and very active during the event, and had the opportunity to comment that:

“ISE 2024 has allowed us to establish contact with potential customers from all over the world, and to learn first-hand about the latest market trends.

The fair has also been an excellent showcase to display our most innovative solutions, such as the Televes IoT Node, which has aroused great interest among visitors”.

Televes IoT NODE

Buildings are key players in our lives that require priority in terms of actions focused on increasing their efficiency, as they are responsible for 40% of global energy consumption. Digitisation is our main ally in the fight to reduce consumption and emissions, increasing the efficiency of these infrastructures. In this respectTeleves presented the IoT Node, a digitisation platform that collects, organises and communicates all the information transmitted by the connected devices deployed in the building, enabling intelligent monitoring by proactively detecting anomalies and carrying out preventive maintenance of the systems, avoiding breakdowns and leaks that could increase energy consumption.

Televes’ participation in ISE 2024 was a resounding success.. The company managed to reach a high number of visitors, mainly integrators and installers of audiovisual services in buildings, who showed great interest in its solutions for the digitisation of buildings, efficient management of resources and the IoT NODE. In this regard, we consider this event as a strategic axis of our communication in the future andwe confirm our presence in future editions of the ISE trade fair.

Congresso AHP (Congresso Nacional de Hotelaria e Turismo) (Madeira, Portugal) 21-23 February

At this event dedicated to the Hospitality sector, our Portuguese subsidiary communicated how our solutions have already equipped more than 30,000 rooms worldwide, with FTTR services offering streaming, VoD, Expand TV, IPTV, Digital Signage, VoIP and Wi-Fi access points.

CES 2024 (Las Vegas, Nevada, USA) 9-12 January

Televes Corporation

Televes Corporation obtains the EN-9100 AENOR certification for aerospace microelectronics

Maxwell Applied Tech, Televes and GCE celebrate the AENOR EN-9100 certification,a Quality Management Systems standard developed by the International Aerospace Quality Group, based on ISO 9001 with additional requirements and interpretations specific to the aerospace and defence industry.

This is a new milestone in microelectronics for the Corporation’s companies, highlighting its commitment to excellence in the production of electronic components.

The EN-9100 certification strategically positions our companies in aerospace microelectronics, facilitating access to international markets. This global standard not only reinforces the trust of the most demanding customers by ensuring high quality and safety standards, but also improves operational efficiency by optimising production and minimising errors.

The ability to participate in critical projects is another key benefit. Complying with EN-9100 allows us to collaborate on aerospace projects that require exceptional levels of micro-component reliability.

Our people

Germán Bentancur. Digital Marketing Technician

In this issue we have the chance to find out more from Germán, who shares his vision of how digitisation can add value to the marketing department at Televes.

What is your job at Televes?

I am a Digital Technician in the Marketing Department, where we are responsible for the design, layout and implementation of the company’s different digital media, such as websites and landing pages for a launch, or a demo for a customer in the Hospitality area, or layouts for internal communications. We even manage the INFO in the Televes website environments, to name but a few.

A very important aspect of our work is to offer cohesion, in terms of design and use, between the different software developments, always trying to make the Televes user feel as comfortable as possible when using our programs and apps.

How long have you been part of the company? How has your career developed?

I have been part of the marketing team since July 2019. Time flies by and in these 5 years I have experienced first-hand a tangible evolution towards user experience, where we think more and more about their needs and how to satisfy them, generating an increasingly complete digital ecosystem of platforms and processes.

What is the most satisfying thing about your job?

One of the things I like most about my job is automating things, making them as fast and simple as possible for the user. Getting someone to feel comfortable and happy using a tool is not easy, but when you do it’s super satisfying.

And the hardest?

It is impossible to have full knowledge of the needs of the target audience; designing blindly is very difficult.

In your opinion, what are the company’s key values?

The technologicalknow-how makes us much more valuable in our industry. By designing and manufacturing our products, we are able to adapt better to the needs of the market.

FAQs

What does “suitable for the industrial environment” mean?

In the telecommunications sector, when a product is labelled as industrial, or for the “industrial environment”, it is guaranteed to meet a series of requirements necessary for installation in these more hostile scenarios. Some of the adverse factors related to environmental conditions are: extreme temperature variations (between -40ºC and +75ºC), presence of dust and particles, vibrations and impacts, or even exposure to chemical substances. Therefore, these products must have a robust design with high temperature dissipation and be easy to install in order to optimise maintenance.

If we translate all these requirements into a specific product, such as industrial switches, we obtain a series of fundamental features:

- metal chassis: for its high resistance to temperature and impact (never plastic).

- airtight design: to protect against foreign particles and substances.

- DIN rail mounting: the star mooring for industrial environments due to its great balance between simplicity and reliability.

These features can be seen in the physical appearance of the product, so it is easy to recognise when a product is truly ready to perform and last in an industrial environment. It is also always advisable to check the manufacturer’s information to ensure that the product is suitable for this purpose

Televes facilities

Volta do Castro'(Santiago de Compostela, Galicia - Spain)

The Volta do Castro public residence in Santiago de Compostela has become a pioneer in the technological transformation promoted by the Regional Government of Galicia. Televes was responsible for supplying and installing the technological solutions at this centre.

The digitisation of the residence consisted of the provision of multi-parametric monitors,which measure users’ health data to establish alerts and personalised guidelines, the configuration of habitaciones inteligentes, con pantallas táctiles y sensores que permiten mejorar la comunicación y el seguimiento de los usuarios, así como los smart roomswith touch screens and sensors to improve the communication and monitoring of users, as well asvirtual rehabilitation systemsto improve users’ physical and cognitive abilities

Ideas

How to use the MOSAIQ6 meter all day long without having to charge it?

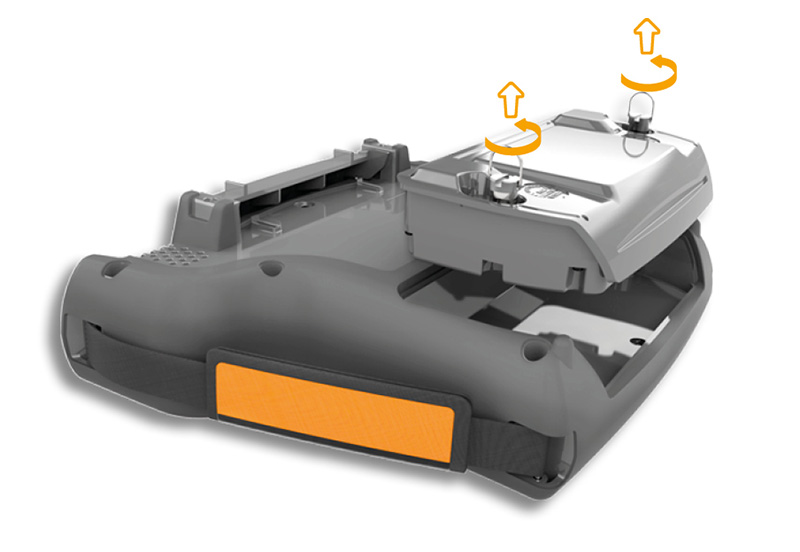

MOSAIQ6 is a high performance portable field meter with 4 hours of autonomy, powering its large 8” screen and using up to 6 widgets at the same time in mosaic mode. On long working days or in scenarios without access to mains charging, a second battery, interchangeable in the field, is the solution to extend its operation for an extra 4 hours..

The battery that comes standard with this meter, in addition to having the operation of a normal battery that is charged when the equipment is connected to the mains, can also be charged independently. The battery can be easily removed from the meter, without the use of tools, and charged without being inserted into the equipment. Therefore,having a second identical battery, and always carrying it charged,allows the installer to make the change at any time of the day, without disassembling the field meter, and without worrying about having to charge the meter to continue with their measurements.

Training

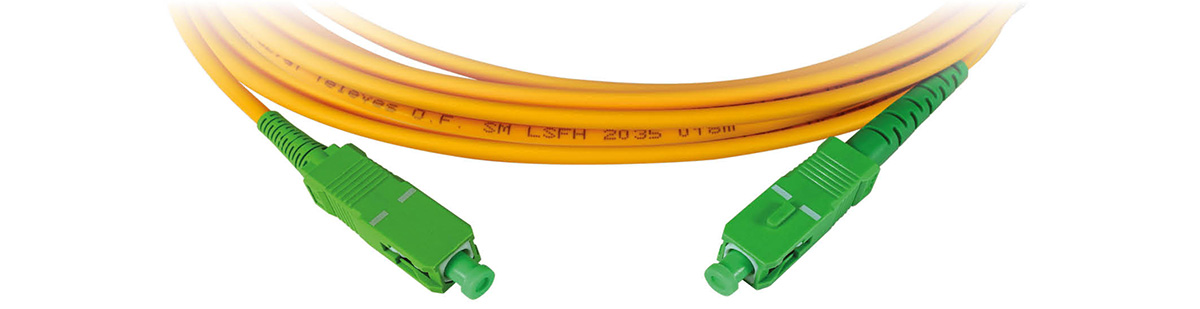

Single-mode fibre classification according to ITU-T G.65x model

Currently, the ITU-T (International Telecommunication Union - Telecommunication Standardisation Sector) defines different specifications for single-mode fibres. The most common on the market is the G-series, within which the G.652 and G.657 specifications stand out and are compatible with each other.

- Zero dispersion fibre: G.652. It is popularly known as standard single-mode fibre, and is the most widely deployed in general purpose optical networks in the industry. It is optimised for the 1310 nm window, although it can operate at 1550 nm with lower efficiency.

- The fibre is insensitive to bending loss: G.657. It supports smaller bending radii, , and is therefore the recommended fibre for FTTH applications and fibre optic networks inside homes where space is limited. It is considered an evolution of G.652 and is therefore slowly gaining market share.

| Types | Categories | Wavelength (nm) | Applications |

|---|---|---|---|

| G.652 | A, B, C and D | 1310, 1550, 1625 (excluding C and D) | LAN, access and CWDM transmission networks |

| G.653 | A and B | 1310 to 1550 | Long distance single-mode transmission systems (EDFA) |

| G.654 | A, B and C | 1550 | Higher bandwidth submarine systems and backhaul systems. |

| G.655 | A, B, C, D and E | 1550 to 1625 | DWDM applications |

| G.656 | - | 1460 to 1625 | CWDM and DWDM long-haul systems |

| G.657 | A1, A2, B2 and B3 | 1260 to 1625 | FTTH |

G.657 fibre and its variants

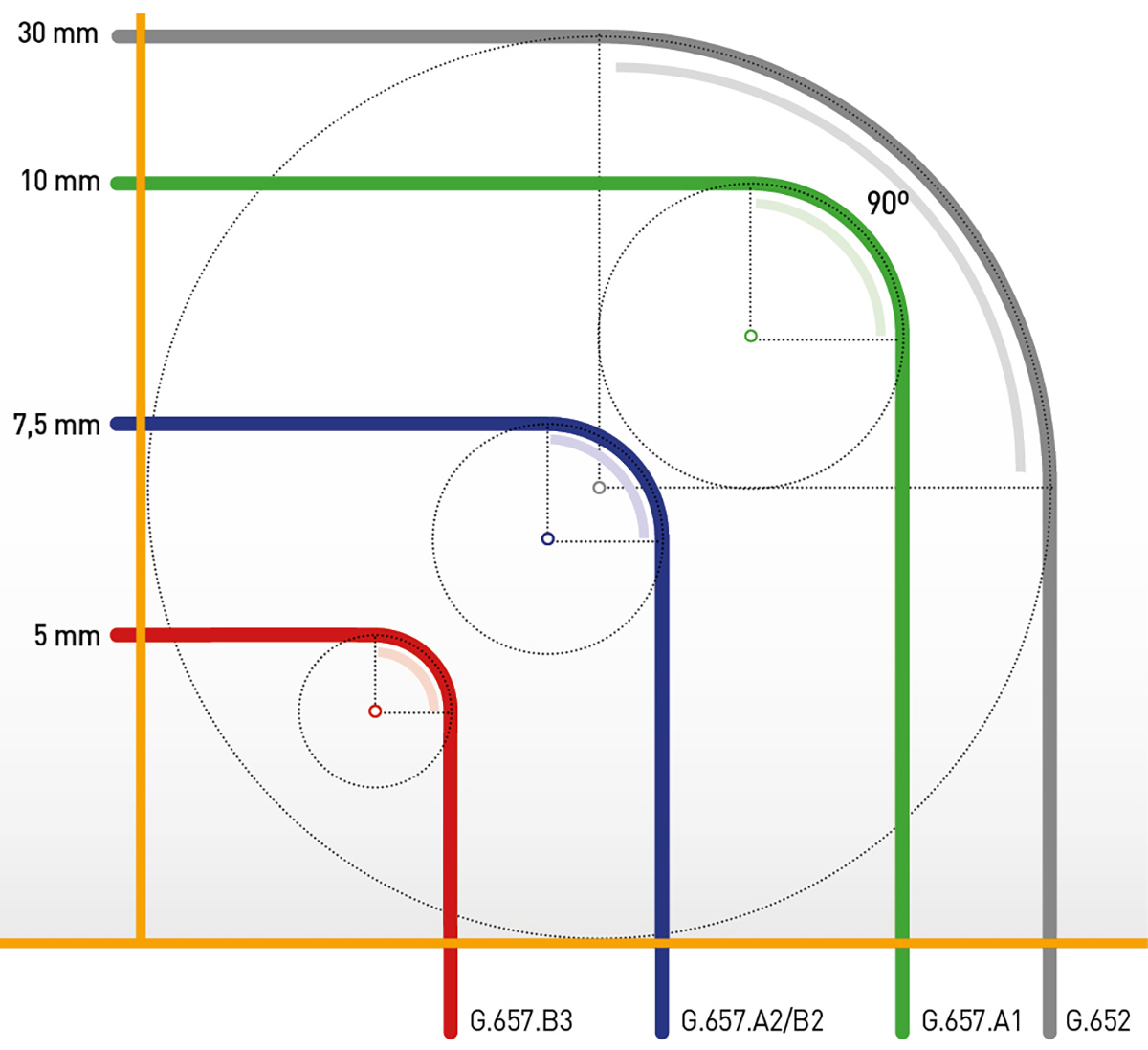

As a technological evolution of G.652, which offers lower attenuations with tighter bending radii, G.657 fibre is experiencing a significant increase in market presence and is already becoming a preference for professionals in the industry.

Type G.657 contains several categories, designed to meet different requirements and to facilitate installation in existing environments:

- Category A: optimised to reduce macro bending losses. It includes two subcategories according to the minimum bending radius: A1 = 10 mm and A2 = 7.5 mm.

- Category B: these are able to further reduce these losses, and are capable of working with extremely small bending radii. It is also subdivided into two subcategories according to this minimum radius: B2 = 7.5 mm and B3 = 5 mm.

The differences between these variants can be decisive in deciding which type is most suitable for which application. For example, within the same category, the A1 variant is the one that supports less bending, and therefore requires more care in installation, whereas A2 is optimised for improved performance at wavelengths 1383 and 1625 nm.

In the case of the ICT spanish regulation, it stipulates the use of single-mode fibre with low sensitivity to bending, that is, type G.657. As a subcategory, it leaves open the possibility of using A2 or B3,the latter being the most tolerant, but also the least demanded in these collective installations.

| ITU-T G.657.A1 | ITU-T G.657.A2 ITU-T G.657.B2 |

ITU-T G.657.B3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Radius | mm | 15 | 10 | 15 | 10 | 7.5 | 10 | 7.5 | 5 | |

| No. of revolutions |

10 | 1 | 10 | 1 | 1 | 1 | 1 | 1 | ||

| Max. attenuation | @1550 nm | dB | 0.25 | 0.75 | 0.03 | 0.1 | 0.5 | 0.03 | 0.08 | 0.15 |

| @1625 nm | 1.0 | 1.5 | 0.1 | 0.2 | 1.0 | 0.1 | 0.25 | 0.45 | ||

Announcement

CIES Crosswalk. SMART LIGHTING TO PROTECT CITIZEN SAFETY